Outcomes Research

Prototyping Protection

HMAC aerosol box minimizes risk during intubation

Each aerosol containment device can be produced at a minimal cost (about $67) using acrylic or transparent polycarbonate sheet. Following each intubation, the HMAC can be reused after a thorough cleaning with 70% alcohol or bleach.

When critically ill COVID-19 patients develop respiratory failure, they often need ventilator support, which requires intubation. The process of inserting an endotracheal tube when placing a patient on a ventilator causes a high rate of contaminated air to be expelled and form aerosols—creating a high-risk situation for health care workers.

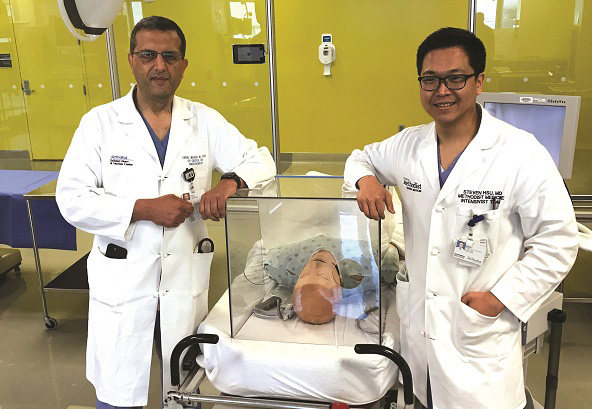

Anticipating an increased occurrence for intubation, two Houston Methodist doctors began seeking safer delivery options for their fellow health care workers. Steven H. Hsu, MD, assistant professor of clinical medicine, Department of Medicine, and Faisal N. Masud, MD, medical director of critical care, Houston Methodist Hospital, and professor of clinical anesthesiology, Departments of Anesthesiology & Critical Care and Cardiovascular Sciences, DeBakey Heart & Vascular Center, developed a way to bring added safety to their co-workers. They designed the Houston Methodist Aerosol Container, or HMAC, a clear plastic box-like protective barrier enclosure that shields clinicians from expelled air when intubating a patient.

The original design came from Dr. Lai Hsien Yung, an anesthesiologist in Christian Mennonite Hospital, Hualien, Taiwan, where I was born, and his family is living in Houston. I found his design and thought, 'This is a great idea to apply during this time of crisis.'

Steven H. Hsu, MD

Assistant Professor of Clinical Medicine

Department of Medicine

Houston Methodist

On the day that the first prototype for testing was delivered, Randolph Steadman, MD, Chair, Department of Anesthesiology & Critical Care, DeBakey Heart & Vascular Center, coordinated testing the first prototype in the Houston Methodist ICU. An additional prototype was deployed to the Emergency Department for testing and intubation purposes. The HMAC continues to evolve during the testing phase. A new prototype, still being tested in the Houston Methodist Institute for Technology, Innovation & Education (MITIE™), adds a vacuum component to remove undesirable aerosol. Using smoke to test air flow in the model, the team confirmed that the vacuum prototype left no particulate matter on the hands while intubating the test dummy. This design is not yet approved for use in clinical care.

Faisal Masud, MD, (left) and Steven H. Hsu, MD, tested and adapted the HMAC, which the FDA approved for emergency use on May 1, 2020.

LaVonne Carlson, March 2020

The vacuum attachment prototype is being checking for smoke absorption by Firas Zabaneh and the MITIE™ team. In the test phase only, it is not used with patients.

Hsu and his colleagues at Houston Methodist made several modifications to the original enclosure to make it more clinician friendly. Along with Firas Zabaneh, MT(ASCP), CIC, CIE, MBA, director of system infection prevention and control, and Trevor Burt, vice president of education administration, they arranged to add a disposable surgical drape to cover the HMAC opening nearest to the patient’s torso, keeping the patient’s head and neck under the enclosure, to further prevent the aerosol from spreading. Another iteration upgraded the holes to be slightly larger for the clinician’s arms. And the final version includes a slanted top panel to enable easier view and control for the clinician. While enhancing the HMAC's utility and safety, these changes also allow the HMAC barrier to be used for bronchoscopy or even nasopharyngeal sampling.

Requests for prototype improvements were met with flexibility by the Houston Methodist Machine Shop. The in-house machine shop, under the direction of lead machinist Juan Fernandez, produced 10 prototype boxes over seven days. Once the final version was selected, the machine shop delivered a total of 50 more HMACs across Houston Methodist’s hospitals within three weeks.

From Taiwan's design to the evolution of HMAC, the aerosol box concept provides frontline health care workers a protective, reusable and low-cost solution to minimize exposure and risks during the pandemic.

Download design files, instructions and specs here.